محصولات

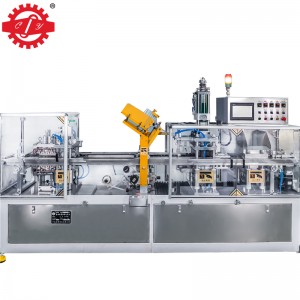

ماشین قالب گیری تزریقی با راندمان بالا برای مسواک

برنامه اصلی

این تجهیزات برای قالب گیری تزریقی مسواک استفاده می شود.این فرآیند تزریق پلاستیک مذاب پلاستیکی شده به داخل حفره قالب بسته با کمک رانش پیچ و به دست آوردن محصول پس از پخت و شکل دادن است.دستگاه قالب گیری تزریقی قادر است محصولات پلاستیکی با ظاهر پیچیده، اندازه دقیق یا بافت متراکم را با درج های فلزی در یک زمان تشکیل دهد.این می تواند بخشی از عملکرد اندام فوقانی انسان را تقلید کند، می تواند به طور خودکار کنترل شود تا مطابق با الزامات برنامه ریزی شده انتقال محصولات یا ابزارهای عملیاتی برای عملیات تولید تجهیزات تولید خودکار باشد.

مقدمه

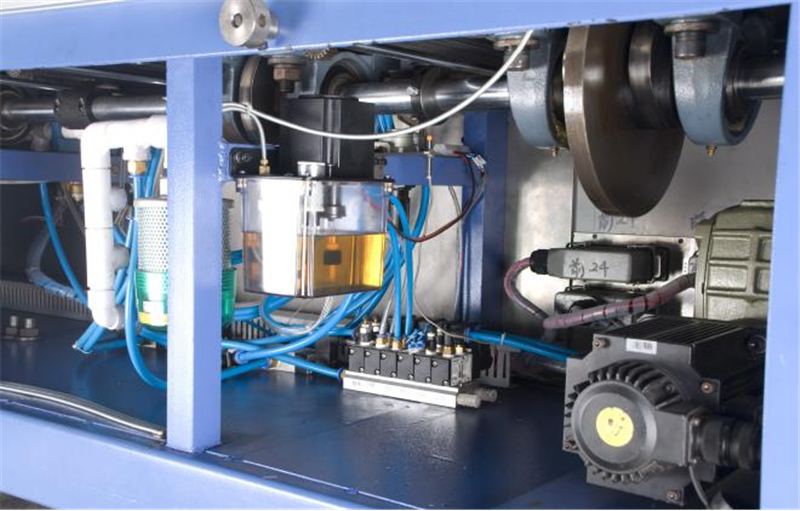

● استفاده از کنترلر سروو با عملکرد عالی، موتور سروو و سایر دستگاه های صرفه جویی در انرژی

● سیستم کنترل سروو حساس، شروع سریع و زمان واکنش کوتاه

● با توجه به بدنه کم دستگاه قالب گیری تزریقی، مواد راحت است و تعمیر و نگهداری آسان است

● کل عملیات دارای صدای کم است که نه تنها به نفع کارگران است، بلکه باعث کاهش سرمایه گذاری و هزینه ساخت در کارگاه تولید عایق صدا می شود.

جزئیات اطلاعات

| قطر پیچ: 42 میلی متر | فاصله باز شدن: 435 میلی متر |

| نسبت L/D پیچ: 23.8L/D | فاصله بین میله های اتصال: 470x470 میلی متر |

| حجم سرسیلندر: 290.8ml | ضخامت قالب: 180-520 میلی متر |

| وزن تزریق: 264.6 گرم | طول انژکتور: 140 میلی متر |

| فشار تزریق: 206.3 مگاپاسکال | نیروی انژکتور: 53KN |

| سرعت تزریق: 99mm/s | تعداد انژکتور: 5 عدد |

| ضربه تزریق: 210 میلی متر | قدرت سروو موتور: 18.7 کیلووات |

| سرعت پیچ: 202r/min | ظرفیت گرمایش: 10.5 کیلووات |

| نیروی بستن: 1780KN | بخش گرمایش: 3+1 |

جزئیات اطلاعات

شفت فرستنده اصلی

ویژگی: 1. موقعیت سنکرون، دقت بالا

2. گشتاور بالا، پایداری بالا، سایش و پارگی کم، سر و صدای کم

+86754-87916365

+86754-87916365

.png) 13342756672

13342756672